Vapour permeability testing for geotextiles and geosynthetics in civil engineering

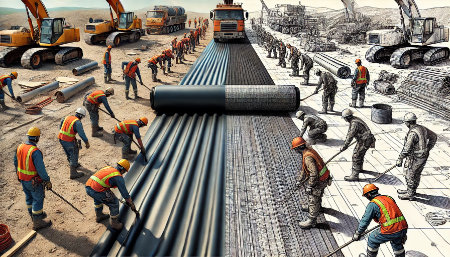

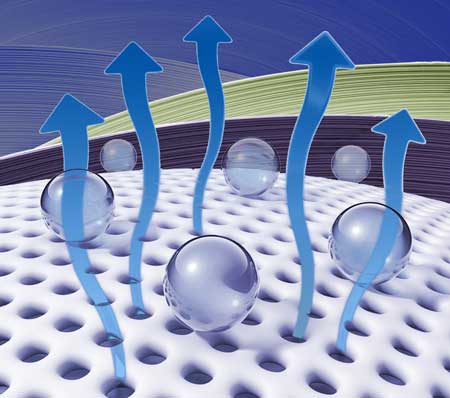

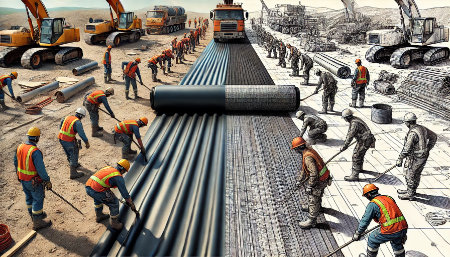

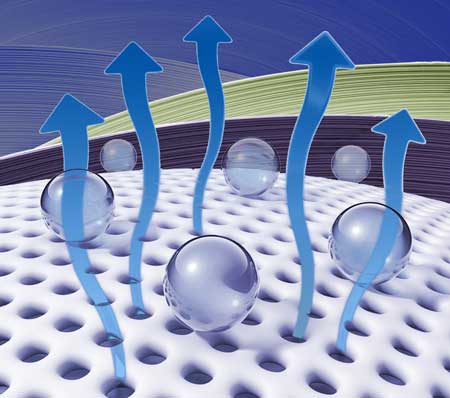

Geotextiles and geosynthetics play a crucial role in civil engineering by enhancing the performance and longevity of infrastructure projects. These materials are used in road construction, erosion control, drainage systems and soil stabilisation. Their effectiveness depends on properties such as strength, filtration and vapour permeability. Vapour permeability testing ensures that these materials allow the controlled movement of moisture and vapour while preventing excessive water retention, which can weaken structures over time.a gas barrier is required. Importantly barriers are also required

for building over areas that release radon, methane or previously contaminated land, where a

barrier to solvents or other chemicals is required.

Uses of vapour permeability testing in geotextiles and geosynthetics Uses of vapour permeability testing in geotextiles and geosynthetics

- Road construction – Ensures geotextiles used in road bases allow proper moisture management, preventing water-logging and maintaining pavement integrity.

- Erosion control – Assesses the ability of geosynthetics to allow vapour movement while preventing soil erosion in embankments and slopes.

- Drainage systems – Evaluates permeability in drainage layers to ensure efficient water flow while maintaining soil stability.

- Soil stabilisation – Tests geotextiles for controlled moisture transfer, preventing excessive drying or saturation that could lead to instability.

- Retaining walls – Ensures geosynthetics used behind retaining structures allow vapour diffusion to prevent hydrostatic pressure buildup.

- Landfills and environmental barriers – Helps design geosynthetic liners that balance permeability with containment to prevent groundwater contamination.

- Tunnel and underground structures – Tests membranes for effective vapour control to prevent condensation and structural degradation.

Advantages of vapour permeability testing for geotextiles and Geosynthetics

- Prevents structural weakness – Reduces the risk of water retention that can lead to soil shifting, subsidence or pavement failure.

- Enhances durability – Ensures geosynthetics maintain long-term performance in varying environmental conditions.

- Improves drainage efficiency – Optimises water movement through filtration layers, preventing flooding and soil erosion.

- Ensures regulatory compliance – Meets UK and international standards for geosynthetic performance in civil engineering applications.

- Supports sustainable construction – Helps select materials that balance permeability with environmental protection.

- Reduces maintenance costs – Prevents water-related damage, minimising the need for repairs and replacements.

UK and international standards for vapour permeability testing of geotextiles and geosynthetics

Vapour permeability testing of geotextiles and geosynthetics ensures compliance with industry standards, guaranteeing material effectiveness in civil engineering applications such as road construction, erosion control and drainage systems. Below is a list of important UK, European and international standards governing permeability testing for these materials.

UK standards (BS - British Standards) UK standards (BS - British Standards)

- BS 6906-1:1987 – Methods of test for geotextiles, including determination of water permeability under normal and hydraulic gradients.

- BS EN 13252:2016 – Specifies requirements for geotextiles used in drainage systems, including permeability testing.

- BS EN 12224:2000 – Assesses the resistance of geotextiles and geosynthetics to degradation under environmental conditions, including vapour transmission.

European standards (EN - European Norms)

- EN ISO 11058:2019 – Measures water permeability of geotextiles and geosynthetic materials by determining the characteristic permeability normal to the plane.

- EN ISO 12958-1:2020 – Tests in-plane water permeability for drainage geosynthetics under different compressive stresses.

- EN 13493:2013 – Specifies requirements for geosynthetic barriers used in waste disposal sites, considering permeability properties.

- EN ISO 16611:2017 – Defines methods for assessing the durability of geosynthetics, including vapour permeability, when exposed to environmental conditions.

International standards (ISO & ASTM)

- ISO 15105-1:2007 – Specifies test method for gas permeability of plastic films

ISO 15105-2:2003 – Specifies test method for gas permeability of plastic films

- ISO 10318-1:2015 – Provides definitions and classifications for geosynthetics, including permeability performance.

- ISO 11058:2019 – Establishes test methods for measuring water permeability normal to the plane of a geotextile or geosynthetic.

- ISO 12958-1:2020 – Standard for in-plane permeability testing of drainage geosynthetics.

- ASTM D4491-21 – Standard test method for measuring the water permeability of geotextiles by permittivity.

- ASTM D4716/D4716M-20 – Tests in-plane flow rate of geosynthetics for drainage applications.

- ASTM D5994-98(2016) – Evaluates the permeability of geosynthetic clay liners used in environmental applications.

Why compliance with these standards is important

- Ensures geotextiles meet performance criteria for drainage, soil stabilisation and erosion control.

- Provides quality assurance for construction projects, reducing failure risks.

- Helps manufacturers and engineers select appropriate materials for different environmental conditions.

- Ensures regulatory approval for infrastructure projects involving geosynthetics.

|

Uses of vapour permeability testing in geotextiles and geosynthetics

Uses of vapour permeability testing in geotextiles and geosynthetics UK standards (BS - British Standards)

UK standards (BS - British Standards)